Why Tubing For Roll Cage Is Necessary?

There are several reasons why a roll cage is important for racing vehicles. Firstly, a roll cage ensures the driver’s safety in the event of a crash. Secondly, it strengthens the chassis of the car and prevents deformation during high-speed impacts. Thirdly, it improves aerodynamic performance by reducing drag and increasing downforce. Lastly, it reduces weight and allows for better handling characteristics. The best tubing for roll cages is typically made from chromoly steel or titanium because of their strength and durability.

Our Top Picks For Best Tubing For Roll Cage

Best Tubing For Roll Cage Guidance

Speedway 1-3/4 OD .109 Wall Mild Steel Roll Cage Tubing, 7 Ft.

Roll cages are an important safety feature in any race car, and they are required by most racing organizations. The main purpose of a roll cage is to protect the driver in the event of a rollover or crash. A roll cage also helps to stiffen the chassis and improve the handling of the car.

Speedway Motors offers a variety of roll cage kits for street stock cars. The kits are made from pre-bent 1-3/4″ diameter, 104 wall HREW 1020 mild steel tubing. The tubing is pre-notched where needed for easy assembly. Some notching is still required. The kits are available in a natural finish or powder coated black.

If you’re looking to add a roll cage to your street stock car, Speedway Motors has you covered!

Common Questions on Speedway 1-3/4 OD .109 Wall Mild Steel Roll Cage Tubing, 7 Ft.

• What is the outside diameter of Speedway 1-3/4 OD .109 Wall Mild Steel Roll Cage Tubing?The outside diameter of Speedway 1-3/4 OD .109 Wall Mild Steel Roll Cage Tubing is 1-3/4 inches.

• What is the wall thickness of Speedway 1-3/4 OD .109 Wall Mild Steel Roll Cage Tubing?

The wall thickness of Speedway 1-3/4 OD .109 Wall Mild Steel Roll Cage Tubing is .109 inches.

• How long is Speedway 1-3/4 OD .109 Wall Mild Steel Roll Cage Tubing?

Speedway 1-3/4 OD .109 Wall Mild Steel Roll Cage Tubing is 7 feet long.

Why We Like This

• Pre bent 1 3/4″ diameter tubing• Made from HREW 1020 mild steel• Tubing is pre notched where needed• Easy assembly• Natural finish

Additional Product Information

| Height | 2 Inches |

| Length | 84 Inches |

| Weight | 12 Pounds |

Speedway Motors Speedy Notcher Roll Cage Tube Joint Tubing Notcher with Instructions, Built-In Protractor Gauge with Degree Angle, Premium Holesaw Blade

Whether you’re building a custom tube chassis, roll cage, or just need to put an angle on some header tubing, the Speedway Motors Speedy Notcher is just the tool for the job. With its built-in protractor gauge, setting the degree of angle you need is quick and easy, and you’ll get perfect notches every time – no more trial and error! This premium tubing notcher can handle 9/16″ to 2″ OD tubing, making it ideal for joining different sized tubes together. It’s also great for anything else you need to put an angle onto, whether it’s round or square tubing. So if you’re looking for a speedy, accurate way to make angled tubing joints, pick up a Speedy Notcher from Speedway Motors today!

Common Questions on Speedway Motors Speedy Notcher Roll Cage Tube Joint Tubing Notcher with Instructions, Built-In Protractor Gauge with Degree Angle, Premium Holesaw Blade

• What is the maximum tubing diameter that can be used with this notcher?The maximum tubing diameter is two inches.

• How many times can the same piece of tubing be used?

This notcher can be used on the same piece of tubing up to five times.

• What is the minimum tubing diameter that can be used with this notcher?

The minimum tubing diameter is one-half inch.

Why We Like This

• Make custom fabricated tube chassis, roll cages and header/exhaust work• Useful in joining different sized tubing• Ideal for anything that you need to put an angle onto the end of either round or square tubing• Incorporates and includes a built in protractor gauge• Makes angled tubing joints quickly and accurately

Additional Product Information

| Height | 8 Inches |

| Length | 12 Inches |

| Weight | 9.3 Pounds |

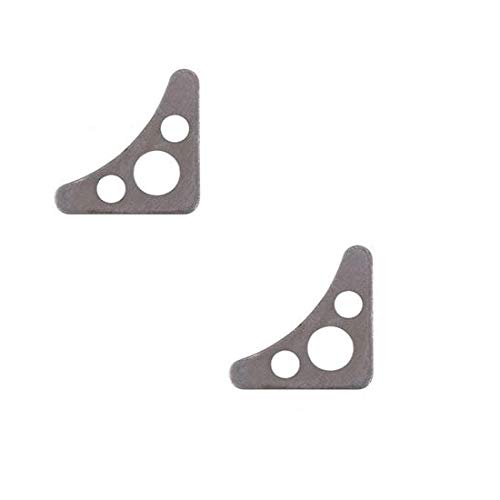

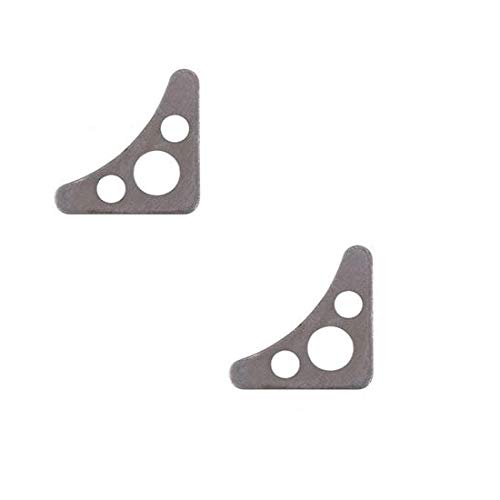

Roll Cage Chassis Bar Steel Weld Gusset Plates w/Holes, 50 Piece

Roll cages are designed to protect a vehicle’s occupants in the event of a rollover or collision. A roll cage is typically made from steel tubing, with steel gussets welded in place to reinforce the joints between the tubing.

The steel tubing used for roll cages is usually between 1.5 and 2.0 inches in diameter, and the tubes are typically connected with steel gusset plates. Gusset plates are metal plates that are placed between two joining pieces of metal, and then welded in place.

Gusset plates help to reinforce the joints between the tubing, and prevent the tubing from crushing in the event of a collision. The holes in the gusset plates also help to distribute the force of a collision evenly, so that the roll cage can better protect the occupants of the vehicle.

Roll cage chassis bar steel weld gusset plates are an important part of any roll cage, and are essential for ensuring the safety of the occupants in the event of a rollover or collision.

Common Questions on Roll Cage Chassis Bar Steel Weld Gusset Plates w/Holes, 50 Piece

• What is the function of a Roll Cage Chassis Bar?The roll cage chassis bar increases the rigidity of the car’s frame, which helps to protect the passengers in the event of a rollover accident.

• What is the difference between a steel weld and a gusset plate?

A steel weld is a type of joint that is created by fusing two pieces of metal together. A gusset plate is a type of plate that is used to reinforce a joint.

• How do you install a Roll Cage Chassis Bar?

The Roll Cage Chassis Bar is installed by welding it to the car’s frame.

• Why are Roll Cage Chassis Bars important?

Roll Cage Chassis Bars are important because they help to protect the passengers in the event of a rollover accident.

Why We Like This

A pack of 50 high quality steel gusset plates with holes, perfect for welding onto a roll cage chassis bar

14 gauge 1 1/2″ x 1 1/2″ gussets and 12 gauge 1 3/4″ x 1 3/4″ gussets

Holes are already drilled into the gussets for easy attachment

Natural steel finish

Low price point

Round DOM Roll Cage Tubing, 1-3/4 x .095 Inch, 7 Foot Length

Round DOM Roll Cage Tubing, 1-3/4 x .095 Inch, 7 Foot Length is manufactured from round DOM steel tubing. It has a 175″ OD and a 0095″ wall thickness. It is sold in pre-cut tube lengths of 3, 7 or 10 feet to better suit your needs. Designed for use in roll cages, race car chassis, roll bars, bumpers, nerf bars, etc.

Common Questions on Round DOM Roll Cage Tubing, 1-3/4 x .095 Inch, 7 Foot Length

• What is the round DOM roll cage tubing made of?The round DOM roll cage tubing is made of 1-3/4 x .095 inch, 7 foot length.

• What are the dimensions of the round DOM roll cage tubing?

The round DOM roll cage tubing has a diameter of 1-3/4 inches and a wall thickness of .095 inches.

• How long is the round DOM roll cage tubing?

The round DOM roll cage tubing is 7 feet long.

• What is the use of the round DOM roll cage tubing?

The round DOM roll cage tubing is used to construct the framework of a roll cage.

Why We Like This

Manufactured from round DOM steel tubing

Has a 175″ OD and a 0095″ wall thickness

Sold in pre cut tube lengths of 3, 7 or 10 feet

Designed for use in roll cages, race car chassis, roll bars, bumpers, nerf bars, etc.

Made in the USA

Additional Product Information

| Height | 1.8 Inches |

| Length | 84 Inches |

| Weight | 12 Pounds |

Competition Engineering C3310 10-Point Roll Cage Strut Kit Only (Main Hoop Kit Sold Separately)

A 10-point roll cage is a type of safety device installed in a racing vehicle. It consists of two main hoops, two door bars, two rear struts, and six mounting pads. The 10-point roll cage is designed to increase chassis rigidity and improve reaction times. It is manufactured from 1-5/8″ x 134″ wall mild steel tubing and all bends are mandrel formed on CNC equipment. The tube ends are notched for better fit and easier installation. The 10-point roll cage meets NHRA and IHRA requirements. The kit comes complete with instructions to ensure a hassle-free installation. Welding is required.

Common Questions on Competition Engineering C3310 10-Point Roll Cage Strut Kit Only (Main Hoop Kit Sold Separately)

• What is the material of the tubing used in the C3310 10-Point Roll Cage Strut Kit Only (Main Hoop Kit Sold Separately)?The tubing is made from 4130 chromoly.

• How many strut bars are included in the kit?

There are 10 strut bars included in the kit.

• What is the minimum diameter of the tubing that can be used with this kit?

The minimum diameter of the tubing that can be used with this kit is 1.5″.

Why We Like This

• 1. Strut kit only for 10 point roll bar main hoops• 2. Meets NHRA requirements for cars running 1099 or quicker with modified firewalls and/or floorboards• 3. Increases chassis rigidity for better reaction times• 4. Manufactured from 1 5/8″ x 134″ wall mild steel tubing• 5. Comes complete with instructions to ensure a hassle free installation

Additional Product Information

| Height | 2 Inches |

| Length | 80 Inches |

Benefits of Tubing For Roll Cage

Roll cages provide a number of safety benefits for racing and off-road driving. They help to keep the driver and passengers safe in the event of a rollover or collision, and they can also help to protect the vehicle itself from damage.

Some roll cages are made from steel tubing, while others are made from aluminum or another metal. There are advantages and disadvantages to each type of material. Steel is stronger than aluminum, but it is also heavier. Aluminum is lighter than steel, but it is not as strong. Ultimately, the best choice of material for a roll cage depends on the specific application and requirements.

When choosing a tubing material for a roll cage, it is important to consider weight, strength, cost, and compatibility with other materials used in the construction of the vehicle (such as welding). For many applications, steel will be the best choice because it offers superior strength at an affordable price.

Buying Guide for Best Tubing For Roll Cage

When it comes to choosing the best tubing for a roll cage, there are several factors that need to be considered in order to make the best decision. The first step is to determine what type of tubing will be required for the specific application. There are two main types of tubing available on the market, including mild steel and chromoly.

Mild steel is the most common type of tubing used in roll cages due to its affordability and ease of fabrication. However, it should be noted that mild steel is not as strong as chromoly and is therefore not recommended for applications where safety is a paramount concern.

Chromoly is a much stronger option than mild steel but is also more expensive. It is important to note that chromoly tubing must be welded in order to achieve its full strength potential. For this reason, it is often reserved for competition-grade roll cages where weight savings and increased safety are essential.

Once the appropriate type of tubing has been selected, the next step is to choose the right size. This will be dictated by the specific requirements of the application as well as personal preference. It is important to remember that larger diameter tubing will result in a heavier cage but will also offer more protection in the event of an accident.

Finally, consider any additional features that may be desired such as mounting points for restraints or lights. These can usually be added after the cage has been constructed but it is always best to plan ahead so that everything fits perfectly once completed.

Frequently Asked Question

What is the best tubing for a roll cage?

The best tubing for a roll cage is chromoly tubing.

What are the benefits of using a roll cage?

A roll cage is a safety device installed in a vehicle to protect the occupants in the event of a rollover accident.

How do I build a roll cage?

Building a roll cage is a fairly involved process that requires some welding and fabrication skills. The basic steps are as follows: 1. Decide on the dimensions and design of the cage. 2. Cut the main cage pieces from square or rectangular tubing. 3. Join the main cage pieces together with gussets at the corners. 4. Add bracing between the main cage pieces for extra strength. 5. Install the cage in the vehicle and weld it in place. 6. Add any additional accessories, such as padding or harnesses.

What are the safety concerns when using a roll cage?

The main safety concern when using a roll cage is that it can impede your ability to exit the vehicle in an emergency. If you are involved in a rollover accident, the roll cage can trap you inside the vehicle and make it difficult to get out. In addition, the roll cage can also make it difficult for emergency responders to get to you and provide assistance.

How can I make my roll cage more comfortable?

There are a few ways to make a roll cage more comfortable. One way is to add padding to the inside of the cage. This can be done by adding foam or other materials to the inside of the cage. Another way to make a roll cage more comfortable is to add a seat. This can be done by adding a seat to the cage or by adding a seat to the vehicle.

Conclusion

If you are looking for the best tubing for roll cage, then look no further than our selection of products. Our tubes are made from the highest quality materials and are designed to withstand the harshest conditions. They are also available in a variety of sizes and lengths to suit your specific needs.